Almost every object we use is developed with computer-aided design (CAD). Ironically, while CAD programs are good for creating designs, using them is actually very difficult and time-consuming if you’re trying to improve an existing design to make the most optimal product.

Researchers from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) and Columbia University are trying to make the process faster and easier: In a new paper, they’ve developed InstantCAD, a tool that lets designers interactively edit, improve, and optimize CAD models using a more streamlined and intuitive workflow.

InstantCAD integrates seamlessly with existing CAD programs as a plug-in, meaning that designers don’t have to learn new tools to use it.

“From more ergonomic desks to higher-performance cars, this is really about creating better products in less time,” says Department of Electrical Engineering and Computer Science PhD student and lead author Adriana Schulz, who will be presenting the paper at this month’s SIGGRAPH computer-graphics conference in Los Angeles. “We think this could be a real game changer for automakers and other companies that want to be able to test and improve complex designs in a matter of seconds to minutes, instead of hours to days.”

The paper was co-written by Associate Professor Wojciech Matusik, PhD student Jie Xu, and postdoc Bo Zhu of CSAIL, as well as Associate Professor Eitan Grinspun and Assistant Professor Changxi Zheng of Columbia University.

Traditional CAD systems are “parametric,” which means that when engineers design models, they can change properties like shape and size (“parameters”) based on different priorities. For example, when designing a wind turbine you might have to make trade-offs between how much airflow you can get versus how much energy it will generate.

However, it can be difficult to determine the absolute best design for what you want your object to do, because there are many different options for modifying the design. On top of that, the process is time-consuming because changing a single property means having to wait to regenerate the new design, run a simulation, see the result, and then figure out what to do next.

With InstantCAD, the process of improving and optimizing the design can be done in real-time, saving engineers days or weeks. After an object is designed in a commercial CAD program, it is sent to a cloud platform where multiple geometric evaluations and simulations are run at the same time.

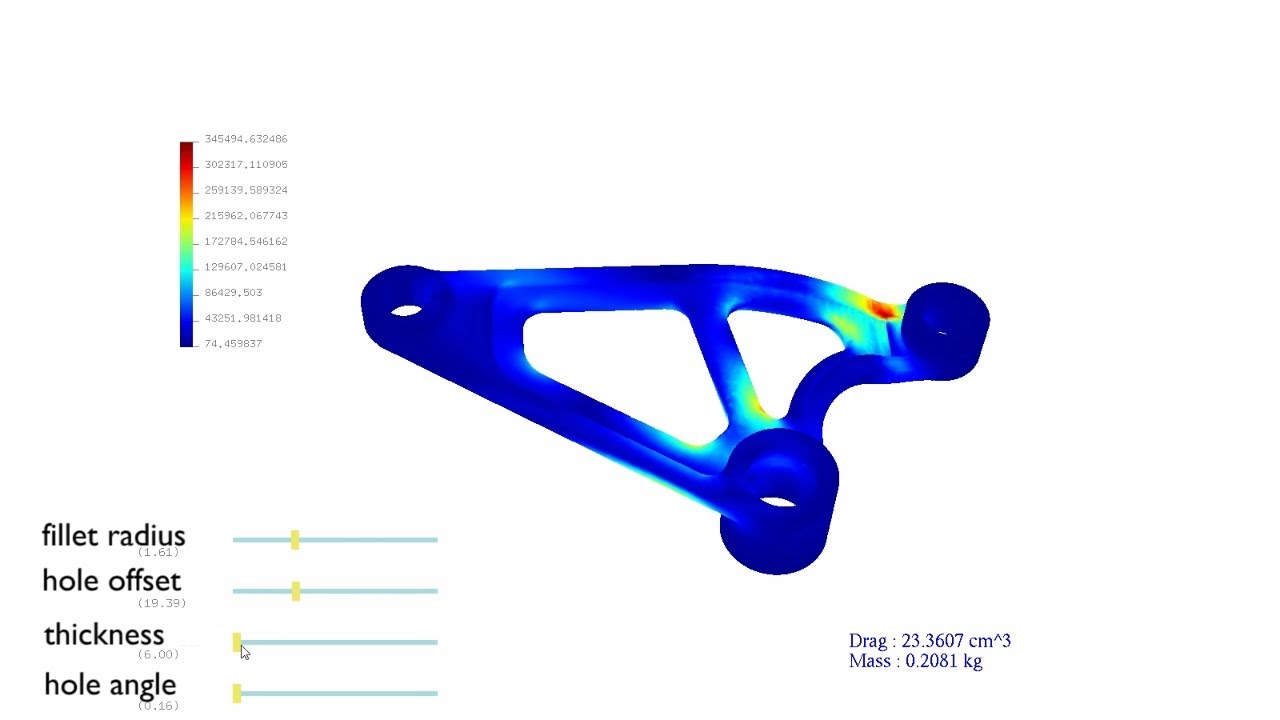

With this precomputed data, you can instantly improve and optimize the design in two ways. With “interactive exploration,” a user interface provides real-time feedback on how design changes will affect performance, like how the shape of a plane wing impacts air pressure distribution. With “automatic optimization,” you simply tell the system to give you a design with specific characteristics, like a drone that’s as lightweight as possible while still being able to carry the maximum amount of weight.

The reason it’s hard to optimize an object’s design is because of the massive size of the design space (the number of possible design options).

“It’s too data-intensive to compute every single point, so we have to come up with a way to predict any point in this space from just a small number of sampled data points,” says Schulz. “This is called ‘interpolation,’ and our key technical contribution is a new algorithm we developed to take these samples and estimate points in the space.”

Matusik says InstantCAD could be particularly helpful for more intricate designs for objects like cars, planes, and robots, particularly for industries like car manufacturing that care a lot about squeezing every little bit of performance out of a product.

“Our system doesn’t just save you time for changing designs, but has the potential to dramatically improve the quality of the products themselves,” says Matusik. “The more complex your design gets, the more important this kind of a tool can be.”

Because of the system’s productivity boosts and CAD integration, Schulz is confident that it will have immediate applications for industry. Down the line, she hopes that InstantCAD can also help lower the barrier for entry for casual users.

"In a world where 3-D printing and industrial robotics are making manufacturing more accessible, we need systems that make the actual design process more accessible, too,” Schulz says. “With systems like this that make it easier to customize objects to meet your specific needs, we hope to be paving the way to a new age of personal manufacturing and DIY design.”

The project was supported by the National Science Foundation.