Even as 3-D printing is poised to help democratize manufacturing, it’s often overlooked that many 3-D-printed items are far too complicated for users to digitally design.

Sure, people can now order 3-D-printed items online, or even make wedding-cake figurines using 3-D-printing services at certain stores. But these are simple, largely standardized products. What if you want a chair or car built to your exact specifications?

Now, a team led by researchers from MIT’s Computer Science and Artificial Intelligence Lab (CSAIL) has developed “Fab By Example,” the first data-driven method to help people design products, with a growing database of templates that allow users to customize thousands of complex items, such as cabinets, jungle gyms, and go-carts.

“When we design things on a computer, the question arises of how to manufacture them in the real world with the necessary physical parts — wood, glass, screws, hinges, bolts and all,” said project lead Adriana Schulz, a PhD student in CSAIL. “For casual users, creating such a detailed model is not just time-consuming, but it’s actually more or less impossible unless you know something about mechanical engineering.”

Fab By Example’s intuitive drag-and-drop interface lets you mix and match materials — and position, align, and connect the different parts — without worrying if the design is actually feasible.

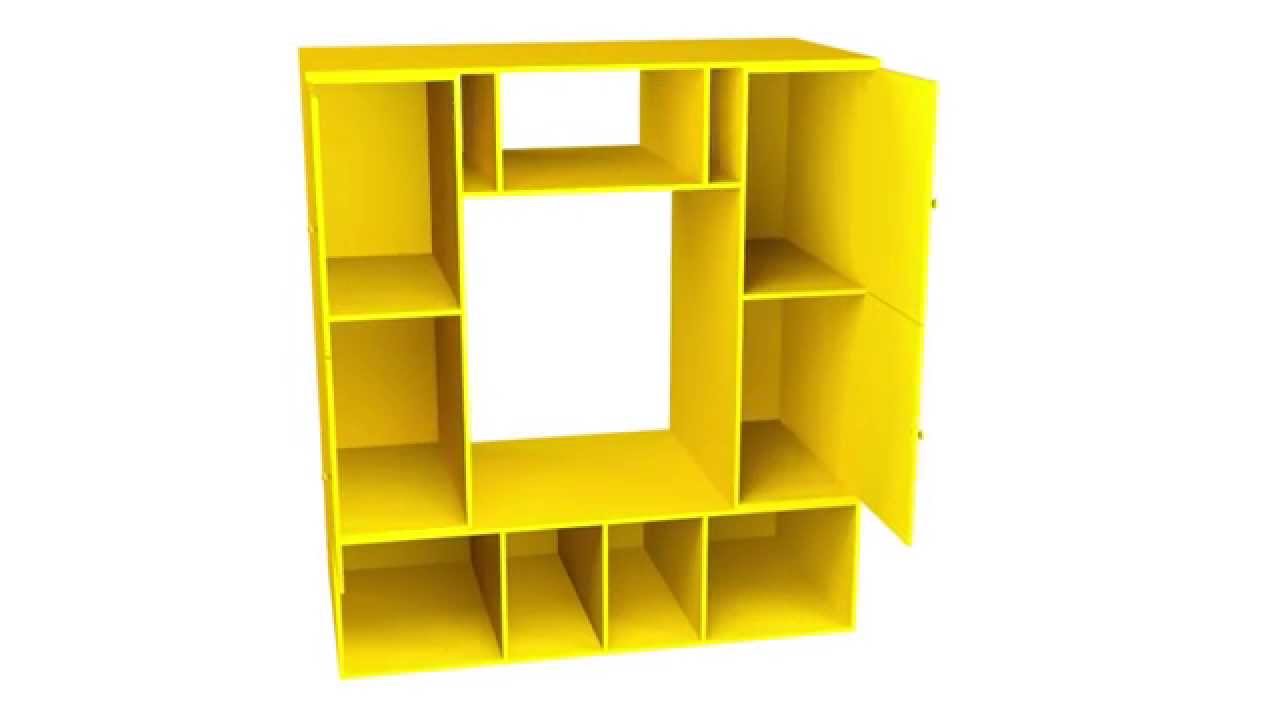

“The technology allows you to design and fabricate practically any off-the-wall idea that’s bouncing around your head,” Schulz said, citing a mega-shelf (pictured above) that takes up nearly an entire room.

The system, which is not yet available to the public, currently has dozens of distinct template models, each composed of hundreds of parts, down to the individual screws of a go-cart. The models are all “parametric,” meaning that they can be manipulated to take on a nearly infinite number of different shapes. Schulz says that the team’s database of templates is currently meant to be illustrative, and could evolve to include models of cars, houses, or practically any fabricable object.

For a given project, Fab By Example allows you to see what specific parts are needed and how much they cost; you could then order the materials right from the database, with the option to optimize for price or speed-of-delivery. (Currently, you’d still need to assemble the product, but Schulz envisions a future where the database could be tied to an installation service that would send someone to your home to build it.)

Where previous do-it-yourself design databases have required an advanced degree, or at least expertise in computer-assisted design (CAD) software, the team says that now even someone with simple computer skills can make a own customizable item.

The work was developed by Schulz; CSAIL postdocs David I.W. Levin and Pitchaya Sitthi-amorn; Wojciech Matusik, an associate professor of electrical engineering and computer science at MIT; and Ariel Shamir, a professor at the Interdisciplinary Center Herzliya in Israel. The team will be presenting its system at this month’s Siggraph graphics conference.

In the future, Schulz says that the team will be working with CSAIL colleagues to incorporate designs for robots that could be assembled, customized, and even printed from home.